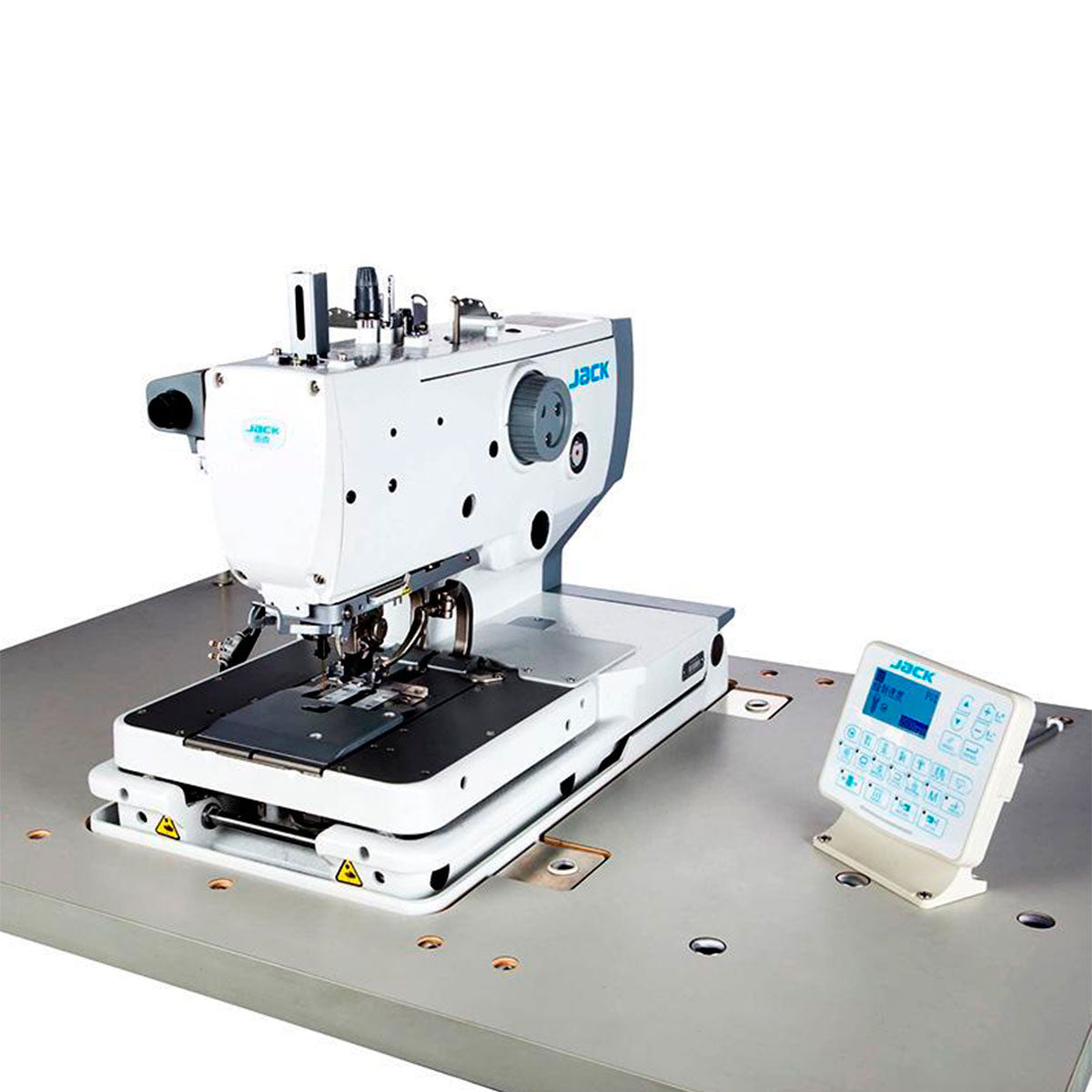

JACK JK-T9820-02 Electronic Keyhole Buttonhole Eyelet Sewing Machine Assembled with Table and Stand Included

JACK JK-T9820-02 Electronic Keyhole Buttonhole Eyelet Sewing Machine Assembled with Table and Stand Included is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Description

Description

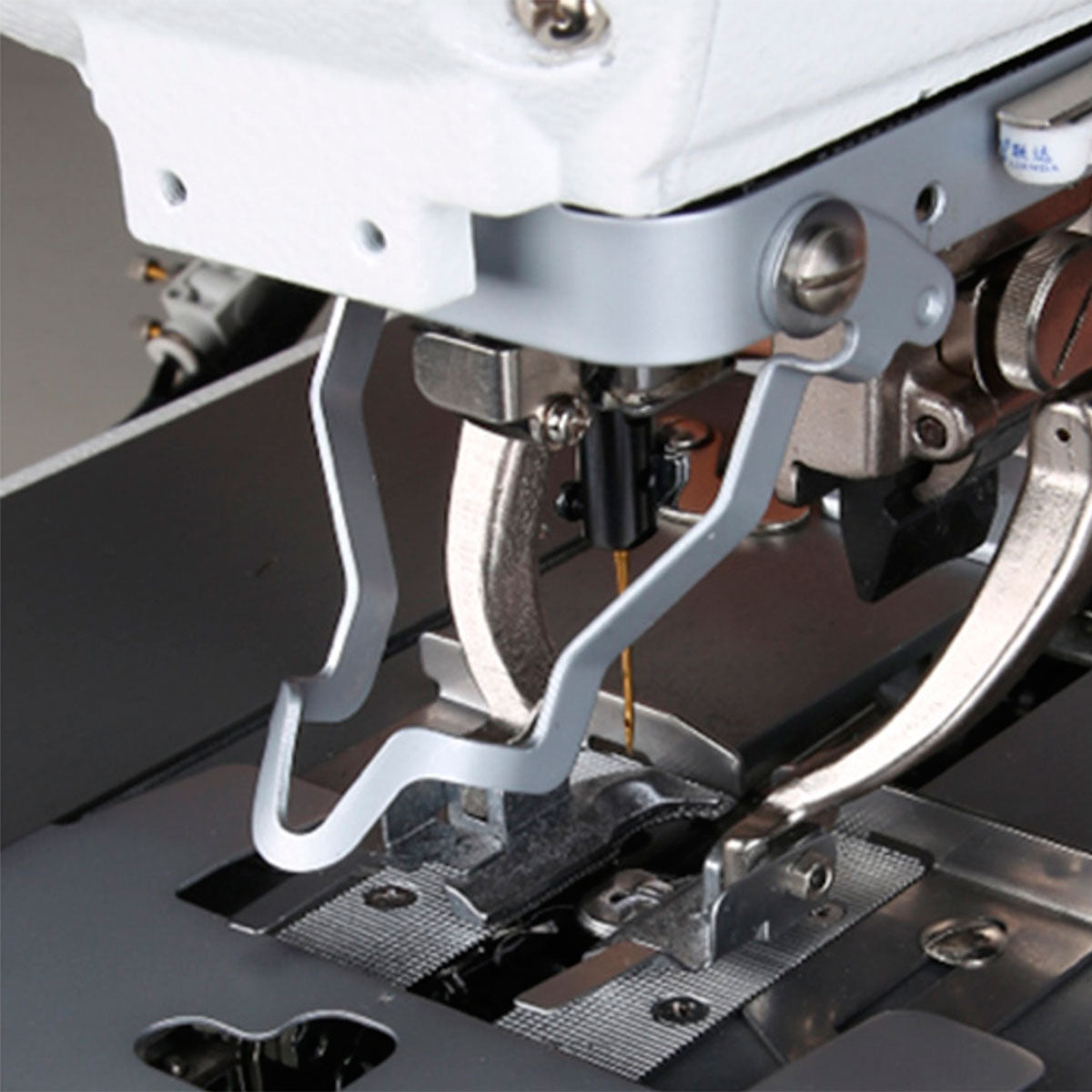

Electronic buttonhole machine for sewing eyelet buttonholes on jeans, pants, jackets, etc.

The machine has a large operating space, beautiful sewing and wide adaptability and variety of buttonholes suitable for multiple operations.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.