SPEEDWAY SW 845 Double Needle Split Bar, Needle Feed Lockstitch Industrial Sewing Machine Assembled with Table and Servo Motor Included

SPEEDWAY SW 845 Double Needle Split Bar, Needle Feed Lockstitch Industrial Sewing Machine Assembled with Table and Servo Motor Included - Standard 1/4" (6.4mm) is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Description

Description

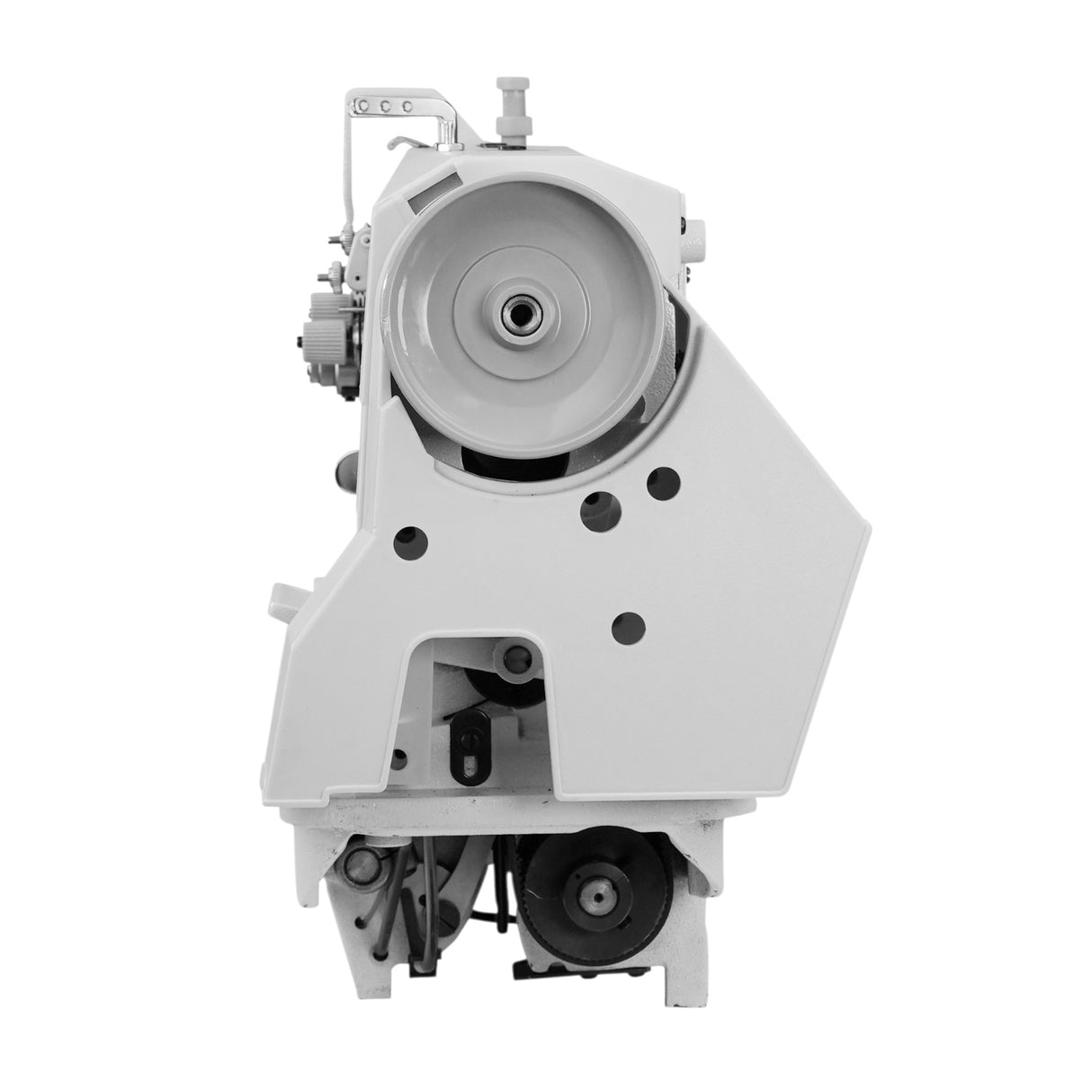

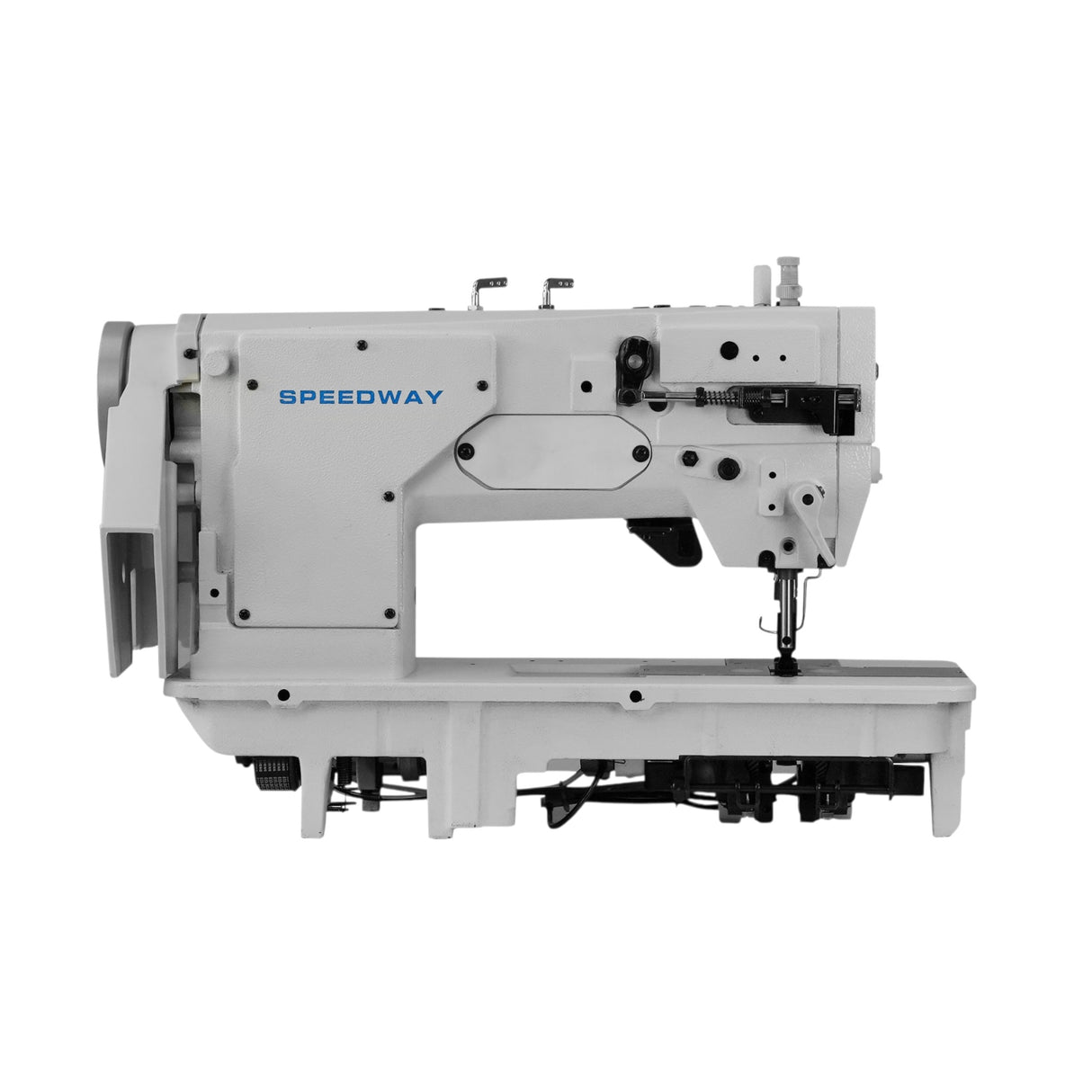

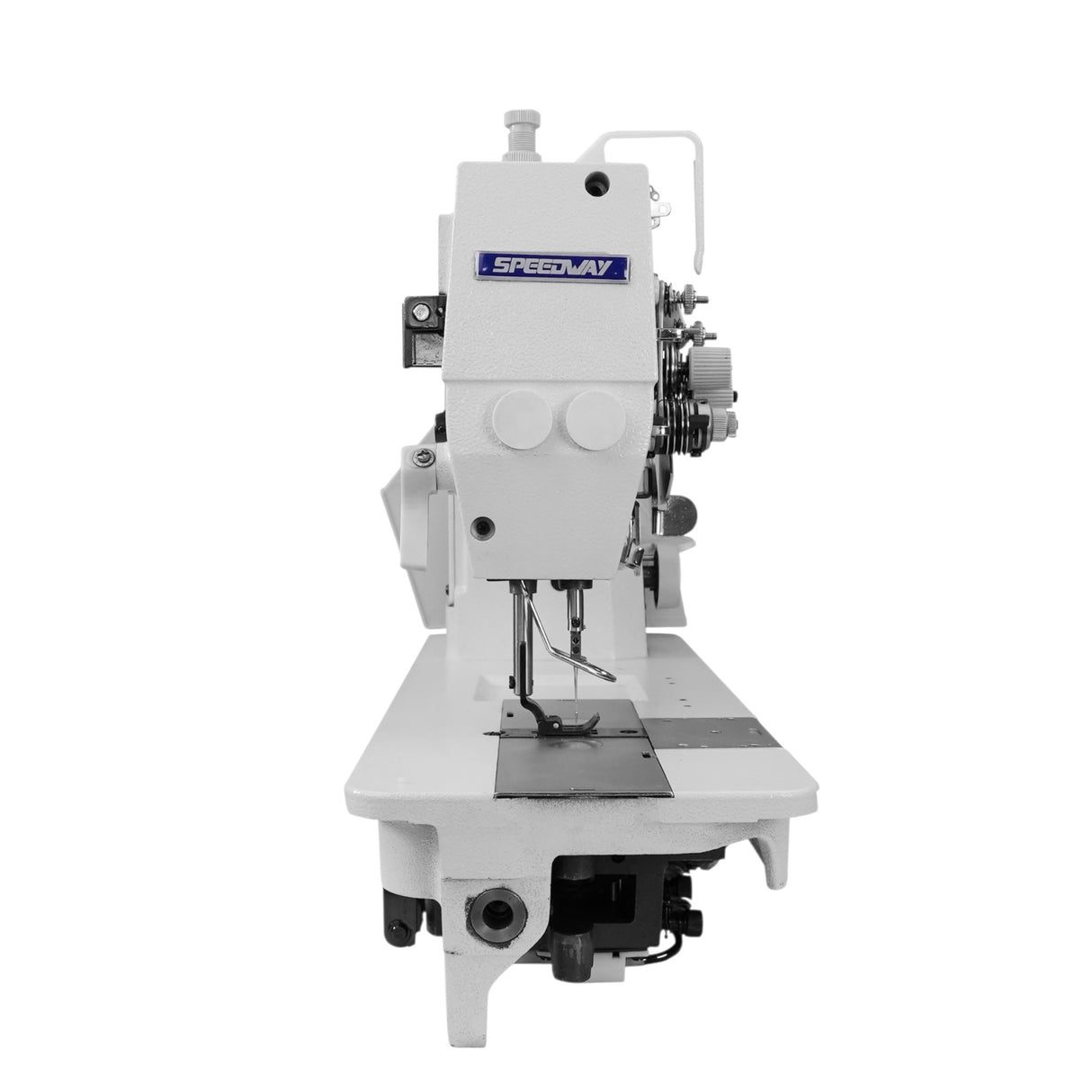

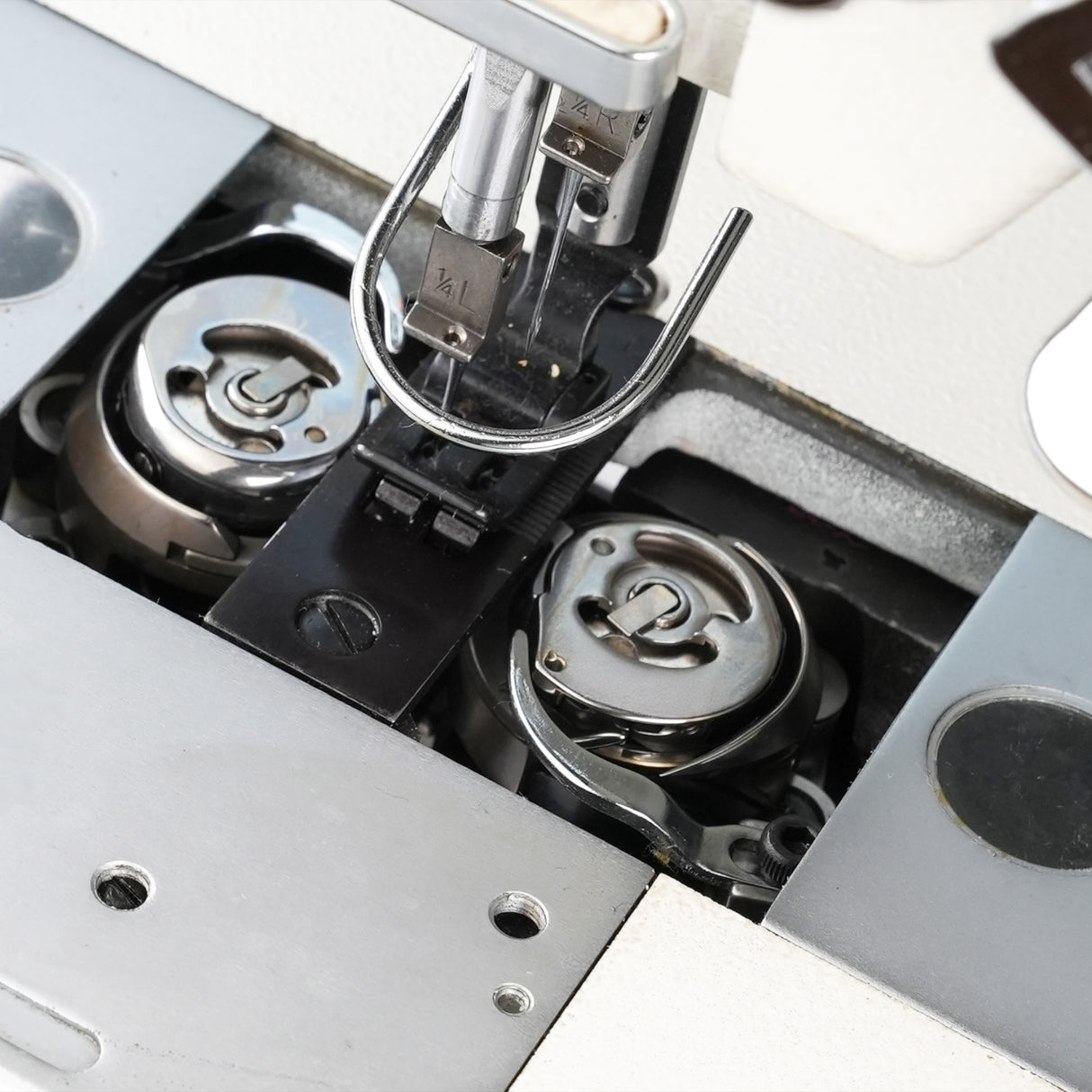

SPEEDWAY® SW-845 Double Needle Split-Bar Needle-Feed Lockstitch Industrial Sewing Machine

Organized Split Needle Bar • Corner & Angle Sewing • Assembled with Servo Motor, Table & Stand Included

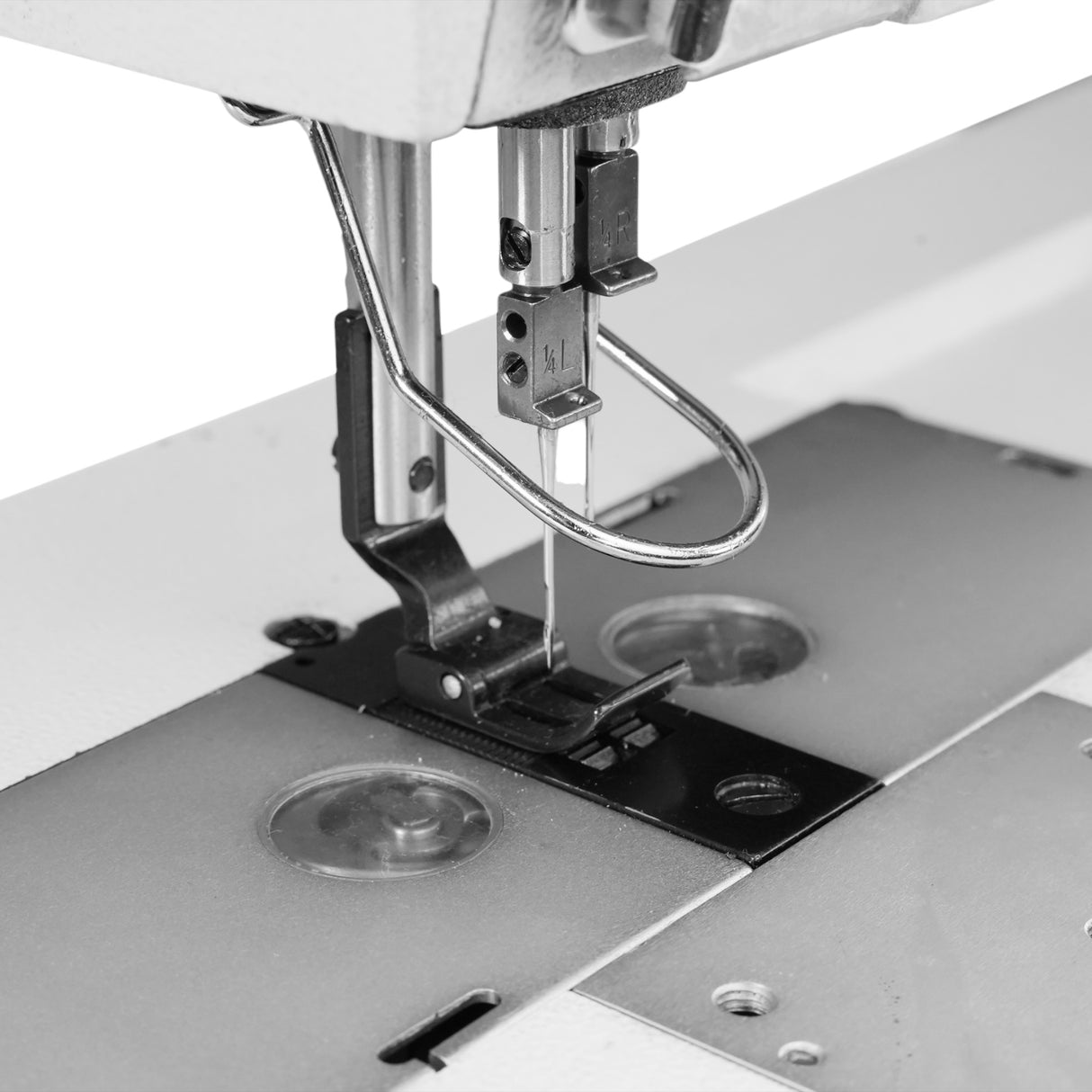

The SPEEDWAY SW-845 is a double-needle, needle-feed lockstitch industrial sewing machine with an organized split needle bar mechanism, designed for high-precision seams where corners, angles and shape transitions matter. Similar in concept to classic “845” and Juki LH3568-style machines, the SW-845 lets you disengage one needle to turn corners and sew tight angles—while keeping the other needle perfectly in line.

Equipped with a needle feed system and standard-size hooks, this machine delivers clean, parallel double-needle seams on medium to heavy fabrics, with a maximum stitch length of 5 mm. It comes fully assembled with a servo motor, industrial table and stand, ready for production.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.